3 min read

Komatsu wins global recognition for breaking industry conventions.

- Press release,Company,Social responsibility,Gentle giants

3 min read

August 7, 2025 -- Operating globally with over 65,000 employees, Komatsu has been at the forefront of innovation within mining, construction and forestry for over 100 years. The Japanese company’s dedication to cutting-edge technology has made it a pioneer in its field, notably going to market with the first ever hybrid hydraulic excavator in 2008.

This relentless drive for innovation was an instigating factor for its reignited partnership with the iconic British Formula 1 team Atlassian Williams Racing. The two brands first worked together in the 1990s, when Komatsu produced gearbox components for the World Championship-winning FW18 and FW19 F1 cars. In this new era, Komatsu and Williams are focused on shared values, talent development, and their surprisingly similar technologies.

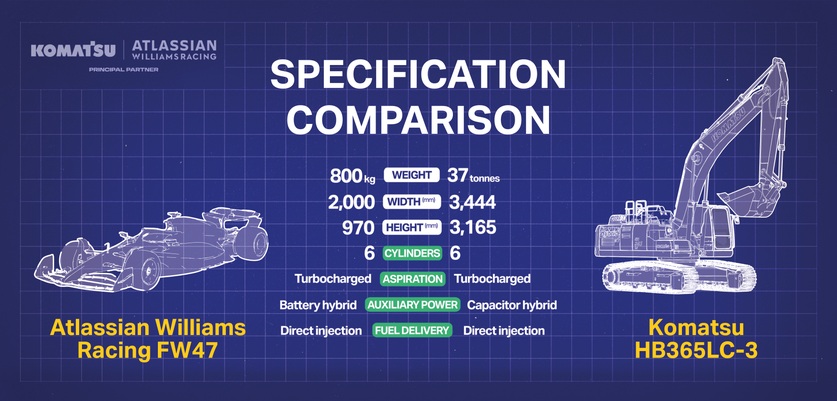

At first glance, the 37 tonne Komatsu HB365LC-3 excavator and high-speed Williams FW47 car look as if they are from completely different worlds. But dig a little deeper and there are myriad common engineering principles and elements, most notably in the form of the hybrid system.

A comparison of the specifications for the Komatsu HB365LC-3 excavator and the Williams FW47 race car.

A comparison of the specifications for the Komatsu HB365LC-3 excavator and the Williams FW47 race car.

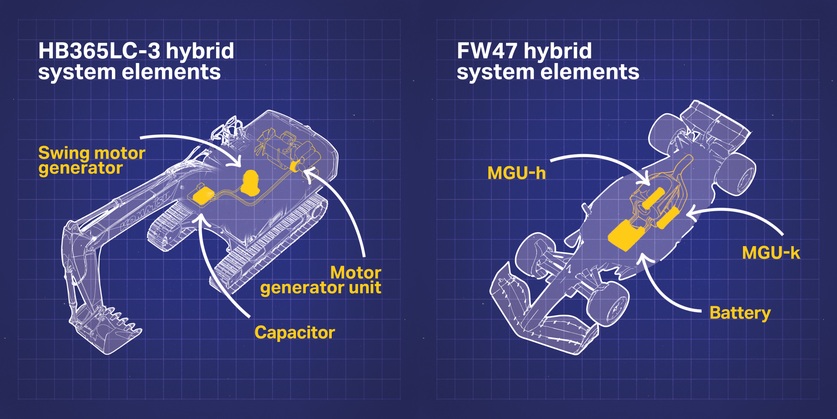

Inside the HB365LC-3 lives Komatsu’s cutting-edge hybrid system, which works alongside a six-cylinder internal combustion engine. How it works is that the machine’s electric swing motor- captures energy as the immense structure slows. The regenerative energy produced during deceleration is then converted into electricity and stored in a capacitor. This source can subsequently be used by the generator-motor to supplement the machine’s power and help the engine accelerate, or to perform the excavator swing function.

The use of hybrid technology during this process can reduce overall fuel consumption by up to.

Komatsu has over a century of experience in electrification, with a track record of producing electric drive mining trucks, ultra-class electric wheel loaders and electric mining and rope shovels. Looking towards the future, the company is now developing the next generation of Power Agnostic mining trucks that will work in conjunction with Komatsu’s Autonomous Haulage Systems.

A comparison of the hybrid system elements of the Komatsu HB365LC-3 and the Williams FW47 race car.

A comparison of the hybrid system elements of the Komatsu HB365LC-3 and the Williams FW47 race car.

Away from the machines, Komatsu and Williams continue to work together on initiatives designed to inspire the next generation of engineering talent. The Komatsu-Williams Engineering Academy was born out of this strive for change, with the programme offering a prime opportunity for 16–20-year-olds from around the world to take the next steps into their STEM futures. Access to mentorship, internships, learning materials and facilities from both companies gives the cohort unparalleled resources to develop their engineering skills.

As a partnership, Komatsu and Williams are creating value together, as well as pushing the boundaries of engineering within their respective fields. And whether it be in some of the harshest conditions on the planet or on the world’s most iconic racing circuits, both companies are dedicated to maximising the power of hybrid technology.